PLM Permanent Lifting Magnets

$315.00 – $1,950.00

The EZ Lift is the safest, strongest permanent lifting magnet on the market. Features built-in safety factor of 3.3 times the rated load.

![]() Government: Also Available Under GSA Schedule 51V , Contract number is GS-06F-0046N Learn about our government capabilities (including NAIC and PCS numbers)

Government: Also Available Under GSA Schedule 51V , Contract number is GS-06F-0046N Learn about our government capabilities (including NAIC and PCS numbers)

International Buyers: Click here to find your global distribution partner.

Description

Shields Permanent Lifting Magnets move the biggest loads

- Rare-Earth “Neo-45” Neodinium Magnet

- 3x Safety Rating and Unique “Safety Lock” Handle Feature

- Tested to hold OVER THREE TIMES the rated load for maximum safety

- Rated for loads up to 4,400 lbs.

- No electricity required

- Eliminates dangerous straps and slings

- Fast, safe, efficient loading and unloading

- Use our application survey to help us determine the correct model for your needs.

- Accessories include Spreader Bars and Vertical Lifters

Load Ratings & Lifting Power

Note: On all our lifting magnets there is a built-in safety factor of 3.3 times the rated load. This means that the safety factor is 3.3 times the maximum rated load for each magnet lifter. All Lifting Magnets need a safety rating; do not be misled by magnets without such.

WARNING: Never lift more than the maximum rated load.

Why Cheap Lifting Magnets Should Be Avoided

| Maximum Rated Load Plate Steel | |||

| Model | Material | Maximum Rated Load | Minimum Thickness |

| PLM-100 | plate steel | 220 lbs. | 0.59″ |

| PLM-300 | plate steel | 660 lbs. | 0.98″ |

| PLM-600 | plate steel | 1,320 lbs. | 1.18″ |

| PLM-1000 | plate steel | 2,200 lbs. | 1.57″ |

| PLM-2000 | plate steel | 4,400 lbs. | 2.16″ |

| Maximum Rated Load Round Steel | ||||

| Model | Material | Maximum Rated Load | Maximum Diameter | Maximum Length |

| PLM-100 | round steel | 99 lbs. | 5.9″ | 40″ |

| PLM-300 | round steel | 300 lbs. | 9.8″ | 60″ |

| PLM-600 | round steel | 600 lbs. | 13.8″ | 80″ |

| PLM-1000 | round steel | 990 lbs. | 17.8″ | 98″ |

| PLM-2000 | round steel | 1980 lbs. | 21.6″ | 118″ |

Percent of Lifting Power (by thickness of material)

| Thickness | Depth | PLM-100 | PLM-300 | PLM-600 | PLM-1000 | PLM-2000 |

| T1 | 2.36 in | 100% | 100% | 100% | 100% | 100% |

| T2 | 2.16 in | 100% | 100% | 100% | 100% | 100% |

| T3 | 1.97 in | 100% | 100% | 100% | 100% | 95% |

| T4 | 1.77 in | 100% | 100% | 100% | 100% | 90% |

| T5 | 1.57 in | 100% | 100% | 100% | 100% | 85% |

| T6 | 1.38 in | 100% | 100% | 100% | 90% | 75% |

| T7 | 1.18 in | 100% | 100% | 100% | 80% | 65% |

| T8 | 0.98 in | 100% | 100% | 90% | 70% | 55% |

| T9 | 0.79 in | 100% | 90% | 75% | 60% | 45% |

| T10 | 0.59 in | 100% | 70% | 60% | 50% | 35% |

| T11 | 0.39 in | 70% | 50% | 45% | 35% | 25% |

| T12 | 0.20 in | 40% | 30% | 25% | 20% | 15% |

Calculation Example: SLM-600, rated lifting power is 1,320 lbs. The formula for calculating range of lifting capacity is: T x F x M x Capacity.

T = Thickness

F = Surface Finish

M = Material

PLM-600 Example: T8, F1 and M2

90% x 125% x 85% x 1,320 = 1,263 lbs

Applications

Use the Model PLM EZ-LIFT lifting magnets to move plate steel, block or round steel, and iron material in your shop. Our super-powerful lifting magnet requires no electricity. This magnet lifter is perfect for loading or unloading most workpieces including press molds, plastic molds, machined parts, etc. Lifting Magnets Rated for up to 4,400 lbs!

WHO USES PERMANENT LIFTING MAGNETS?

Pipeline Builders

Workshops

Contractors

Engineering Firms

Steel Foundries

These units are the ideal solution for machined parts, press molds and other uses around the foundry. SLM Lifting Magnets eliminate the need for dangerous straps and slings that can slip or break.

Municipalities

Use PLM magnets to quickly remove both smooth and grid manhole covers, as well as re-position sewer covers and other street coverings. They also allow workers to easily lift plate steel during street re-surfacing or other road work.

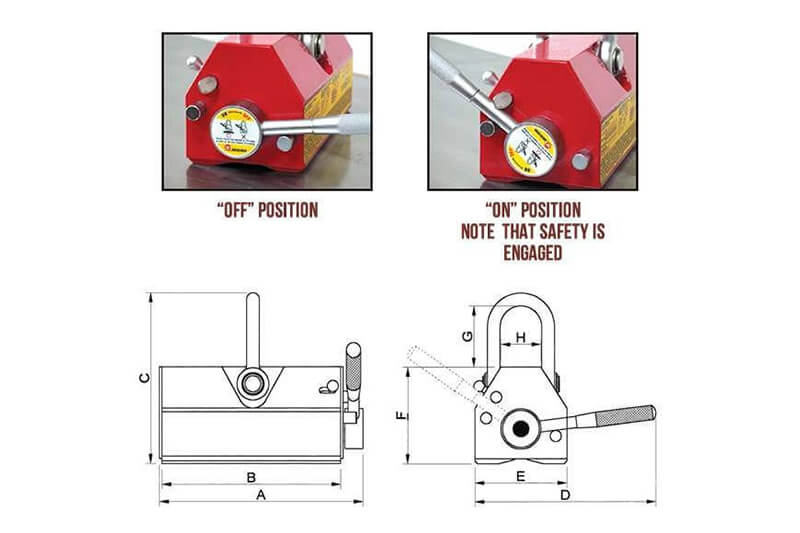

Lifting Magnet Operation

Simply move the lever to the “ON” position to engage the lifting magnet. Spring-loaded lock keeps the magnet engaged until you release it.

|

|

Lever in the “OFF” position.

|

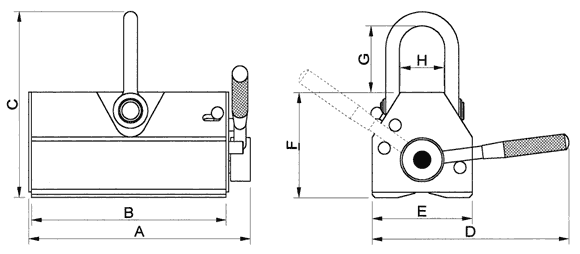

| Part No. | Plate | Round | A | B | C | D | E | F | G | H | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PLM-100 | 220 lbs. | 99 lbs. | 4.2″ | 3.3″ | 4.7″ | 4.9″ | 2.4″ | 2.8″ | 1.6″ | 1.2″ | 5.5 lbs. |

| PLM-300 | 660 lbs. | 300 lbs. | 7.1″ | 6.1″ | 6.1″ | 7.3″ | 3.6″ | 3.7″ | 2.0″ | 1.6″ | 18.9 lbs. |

| PLM-600 | 1,320 lbs. | 600 lbs. | 10.0″ | 8.8″ | 8.3″ | 10.2″ | 4.5″ | 4.7″ | 3.0″ | 2.0″ | 46 lbs. |

| PLM-1000 | 2,200 lbs. | 990 lbs. | 11.0″ | 9.6 | 11.3″ | 14.6″ | 6.5″ | 6.7″ | 3.8″ | 3.4″ | 101 lbs. |

| PLM-2000 | 4,400 lbs. | 1,980 lbs. | 16.6″ | 15.0″ | 13.7″ | 20.2″ | 8.5″ | 8.5″ | 4.1″ | 4.8″ | 259 lbs. |

| PLM-3000 | 6,600 lbs. | 2,970 lbs. | 22.3″ | 20.9″ | 15.7″ | 30.3″ | 8.5″ | 8.7″ | 5.8″ | 3.2″ | 399 lbs. |

Material Handling Accessories

EZ-Lift Spreader Bars

Spreader bars help keep large or irregular loads under control during transport. You can increase your lifting power by adding more lifting magnets. Includes bar, 1 upper and 2 lower S.P.A. shackles. Order lifting magnets separately.

- For better overall balance

- Use with multiple lifters

- Lifter span adjustable

| Model | Capacity | A | B | C | D | E | F | Weight |

|---|---|---|---|---|---|---|---|---|

| PLM-SB250 | 250 lbs. | 36″ | 18″ | 12″ | 5.1″ | 1.25″ | .85″ | 20 lbs. |

| PLM-SB500 | 500 lbs. | 46″ | 22″ | 16″ | 5.7″ | 1.35″ | 1.34″ | 25 lbs. |

| PLM-SB1000 | 1,000 lbs. | 72″ | 36″ | 24″ | 6.9″ | 1.35″ | 1.34″ | 65 lbs. |

| PLM-SB2000 | 2,000 lbs. | 72″ | 36″ | 24″ | 7.3″ | 2.02″ | 1.35″ | 115 lbs. |

| PLM-SB4000 | 4,000 lbs. | 77″ | 41″ | 24″ | 10.5″ | 2.43″ | 1.63″ | 195 lbs. |

| PLM-SB8000 | 8,000 lbs. | 96″ | 48″ | 24″ | 12.3″ | 2.94″ | 1.78″ | 300 lbs. |

| PLM-SB10000 | 10,000 lbs. | 116″ | 56″ | 24″ | 14.7″ | 3.5″ | 1.65″ | 600 lbs. |

| PLM-SB13500 | 13,500 lbs. | 140″ | 68″ | 36″ | 17.1″ | 4.0″ | 2.02″ | 880 lbs. |

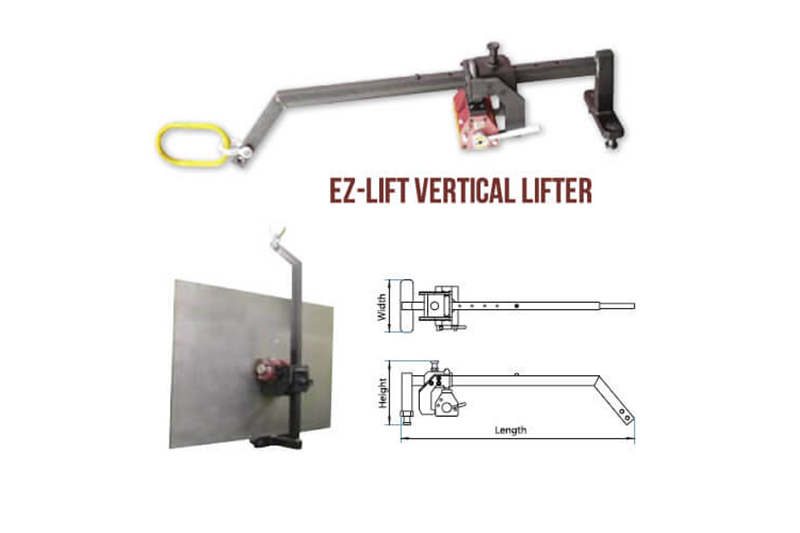

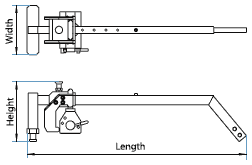

EZ-Lift Vertical Lifters

Used for vertical transport of plate stock for fabricating, machining, etc. Includes super-powerful neodymium iron boron lifting magnet that requires no electricity and will never wear out.

|

Position lifter on stock and turn on magnet. Hoist into vertical position for transport. Always follow operating instructions included. |

| Plate Size (L x W x H min/max) | ||||

|---|---|---|---|---|

| Model | Capacity | L (min/max) | W (min/max) | H (min/max) |

| PLM-300V |

660 lbs.

|

8″/60″

|

11.8″/31.5″

|

0.25″/5.9″

|

| PLM-600V |

1,320 lbs.

|

12″/72″

|

11.8″/39.4″

|

0.31″/9.8″

|

| PLM-1000V |

2,200 lbs.

|

12.5″/79″

|

11.8″/39.4″

|

0.39″/11.8″

|

| Model | Size L x W x H | Weight |

|---|---|---|

| PLM-300V |

37.5″ x 8.5″ x 10″

|

57 lbs.

|

| PLM-600V |

46″ x 11″ x 10″

|

86 lbs.

|

| PLM-1000V |

48″ x 14″ x 12″

|

128 lbs.

|

Frequently Asked Questions

Q. How do I choose what size lifting magnet I need?

A. Refer to the load ratings and power tab which identifies capacities. If you have any questions, just call us!

Q. Do you have all sizes of lifting magnets in stock?

A. Yes, we try to always have units in stock for immediate shipment.

Q. Can these units ship by air?

A. Yes, they are packed according to required guidelines for shipping magnets.

Q. Do your lifting magnets have safety features?

A. Yes, all units have locking handles and a 3x safety rating.

Q. What is the lifting magnet made of?

A. The magnet itself is a Rare Earth, Neodinium Magnet encased in a steel/alloy housing.

Q. Do lifting magnets work with paint?

A. Yes. You may need to move up one size to accommodate the coating thickness if it’s more than 1 mil but otherwise the size should remain constant

Q. Do lifting magnets work on round steel as well as flat?

A. Yes, our lifting magnets have ratings for both plate and round steel.

Q. Will the magnets work on waffle patterns?

A. Yes but you will need to move up to the next larger size

Q. Do I need one or two lifting magnets for my application?

A. If the weight is in the required range but the steel is longer than the stated maximum safety length, you would need two units on a spreader bar.

Q. Are the bottoms flat or curved?

A. The bottoms are convex so they can accommodate both flat and round steel per the weights shown on the chart

Q. What does a 3x safety rating really mean?

A. It means that under perfect conditions, which rarely exist, the magnets will hold 3x their rated loads. In other words, the steel would have to be perfectly clean, flat and within the dimensional requirements shown on the chart. This is a “safety” rating used to insure that users don’t overstep the limitations of the magnets.

Q. Can you use these under water?

A. Yes, water does not damage them or decrease magnetic field. Salt water will however, corrode them over time.

Additional information

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Model |