Cross-Belt Magnets

We Have Most Sizes In-Stock and Ready for Immediate Shipment!

Use Our Quick and Easy 3-Step Process:

Step 1. Click on the “Start Criteria” button below and provide the requested information (if you don’t know it all it’s ok).

Step 2. We will contact you to let you know your criteria was received and collect any additional information needed.

Step 3. We will provide a quote including specs, lead time and cost within 24 hours.

Description

Companies Rely on Shields Belt Magnets

Features and Benefits

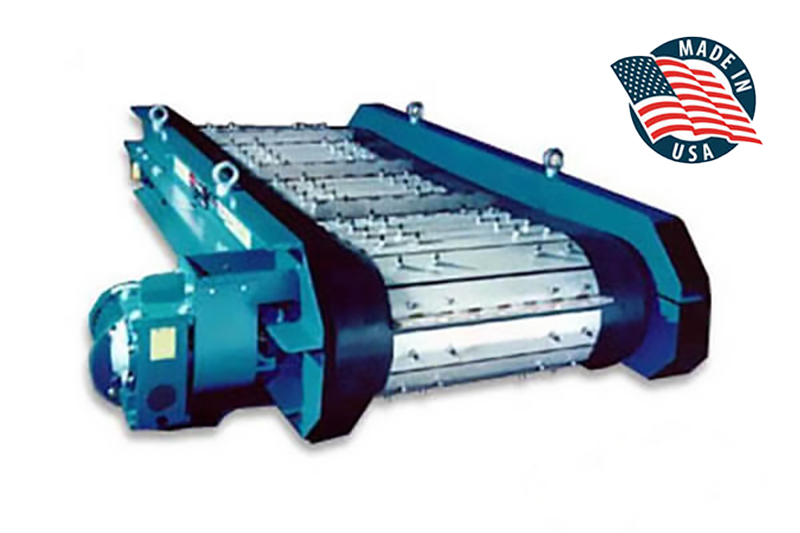

Crossbelt or belt magnets, also known as overhead magnetic separators, offer a practical and efficient method for separating ferrous metal from fast-moving materials on conveyors. Our belt magnets utilize Tri-Polar Magnetic Circuitry, exclusive to the industry!

- Crossbelt magnets reclaim a higher percentage of valuable steel

- Belt Magnets Easily interchangeable from one machine to another

- Custom designed to suit your make and model of crusher

- Permanent Self-Cleaning Magnets are virtually maintenance-free

- Non-deteriorating belt magnet system

- Supplied with easy-to-follow operators manual

PCB

Our PCB Series of Belt Magnets are the #1 Self-Cleaning Magnets sold in North America. The PCB magnets are standard on portable and stationary crushing, shredding, grinding, screening and recycling plants, with thousands in operation throughout the world. Recycling operations include MRFs, C & D, crushed concrete/asphalt, scrap wood, crushed glass, scrap tires and other solid waste applications. These are just some of the uses for these magnets, they are operating in many other industries with great success.

The Self-Cleaning Recycling Magnets are Permanent Magnets using the latest and highest grade of materials suitable for this type of magnet system. When compared to electro magnets, no electrical source is required for the magnet, it is considerably lighter in weight, has a lower profile, is virtually maintenance free and less expensive to purchase, install and operate. In most applications the Type ’K’ have many advantages over an electro magnet. Our crossbelt magnets are available with both electric or hydraulic drives for the belt system.

Earlier solutions to tramp iron and ferrous metal separation, be it rebar, wire, screening, drill steel, loader teeth, sledgehammers, nails, tin cans etc…, from the material being processed has been to utilize belt-pickers or metal detectors. While both are expensive alternatives to our Self-Cleaning Magnets, the metal detector will also continuously shut down the process if too much ferrous is present.

Companies that use our Self-Cleaning Magnetic Separators have reported back that they have recovered the original cost in as little as two months due to reduction in manpower expense, minimal production stoppages, higher percentage of reclaimed scrap and upgraded, higher quality end product.

The magnet block enclosed in this system is powerful, computer designed, and mounted in a heavy-duty steel frame. The magnet is traversed with a heavy-duty vulcanized cleated belt running on two crowned pulleys and driven by either an electric or hydraulic motor, depending on the application. The entire system is designed for durability and is able to operate in the harshest environments. Stainless steel magnet and belt guards on both sides of the magnet are standard and run the full length for safety of workers and protection of the system.

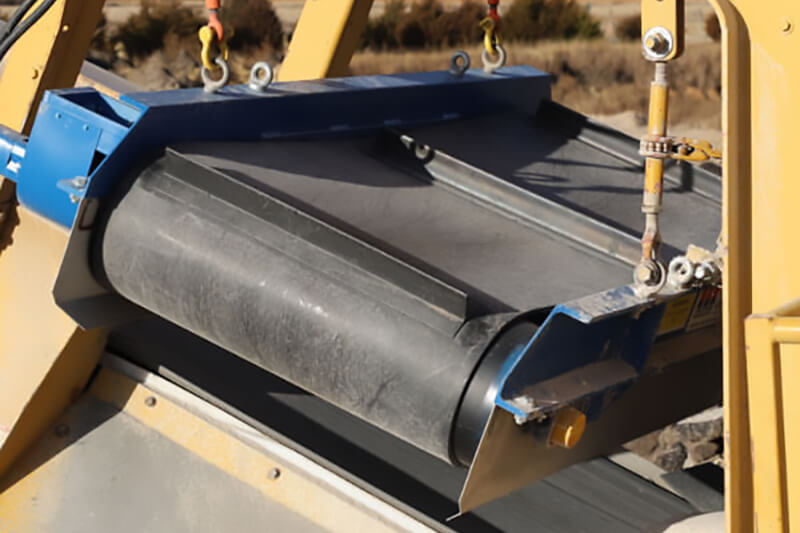

These overhead magnet systems are normally suspended by their eyebolts, over the conveyor at a specific distance, called the “working gap” – the distance from the magnet face to the bottom of the processed material. Normally suspended from a goal post, A-frame or 4-poster type steel structure, they are available for both crossbelt (perpendicular to the conveyor processing the material) and in-line applications (same direction as the conveyor and over the head pulley). As tramp ferrous metals pass underneath the magnet and become attracted to the face of the magnet, the cleated belt moves the metals clear of the conveyor burden transporting it out of the magnetic field, discharging it away from the conveyor.

Crossbelt Magnet Applications

Crossbelt magnetics are commonly used in a wide variety of industrial settings including:

- Recycling Crushed Concrete

- Recycling Tires

- Recycling Pallets

- Recycling Solid Waste

- Aggregate Processing

- Solid Waste & MRF’s

- Steel and Slag Processing

- Power Stations

- Milling

- Paper Packaging

Why Choose a Shields

- Stronger magnetic fields than competitors by upwards of 15% (when comparing like sizes)

- Magnetic strength warranted for life (against loss of strength)

- Tri-Polar© Magnetic Circuitry – Standard on belt magnet series 12PCB, 14PCB & 16PCB (optional on all others)

- Prevents magnetic field peripheral leakage

- Lowers incidences of surrounding frames, structures and idlers from becoming magnetized

- Achieves better tramp metal extractions

- Overhead magnets assist in reducing conveyor belt damage

- Manganese impact plate on 12PCB, 14PCB & 16PCB belt magnets; stainless steel impact plates on all others

- Available with electric direct-drive or hydraulic motors to operate self-cleaning belt on magnet

- Belts on magnet systems, heavy-duty fitted with vulcanized Beefy T-Cleats that will not separate from belt or can be pried loose

- Armor-clad belts using HDPE with results equivalent to stainless steel, but without weight and cost

- Stainless steel guards (to protect belt and magnet block), fitted as standard on BOTH sides of magnet system

Tri-Polar Circuitry Delivers Improved Magnetic Strength

Exclusive to the industry, our magnetic separators utilize tri-polar magnetic circuitry. This eliminates most peripheral magnetic leakage and directs the magnetic field straight down, improving and increasing the strength compared to equivalent sized magnets. This technology is not available from any other magnet system manufacturer in North America. Magnetic intensity in excess of 400-500 gauss at the recommended working gap retained permanently when used under normal operating conditions.