Overhead Magnetic Separators & Conveyor Magnets

Cities are the hub of large operations that make use of heavy equipment to create stone products for construction. Here, earth-movers and belt conveyors work together with machines designed specifically for crushing aggregate into different sizes depending on its purpose. Aggregate facilities also exist which process reclaimed concrete as recycled materials – a smart way to reduce landfill waste whilst providing valuable resources for future building projects! At these plants featuring overhead magnetic separators, metal is efficiently removed from each portion of reused concrete before it can be repurposed in new structures and roads.

Our industrial magnets carry a lifetime guarantee on strength

Utilizing state-of-the-art technology and the most advanced materials available, Shields magnetic sweepers are innovative, functional, and effective. Our entire line of sweepers carries a lifetime guarantee on strength and a full product performance guarantee. All of our industrial magnets originate in the USA.

Ensure product purity, protect equipment and prevent downtime

Adding overhead separators, drum magnets or crossbelt magnets can save your organization thousands of dollars in lost product, materials, damage to your production equipment and help improve up-time. Our magnetic separators use powerful Grade 8 permanent magnets and can be ordered to spec, including electromagnets. We’ll work with your to customize a separation system that will fit your facility and application perfectly.

Companies That Rely on Shields Magnetics

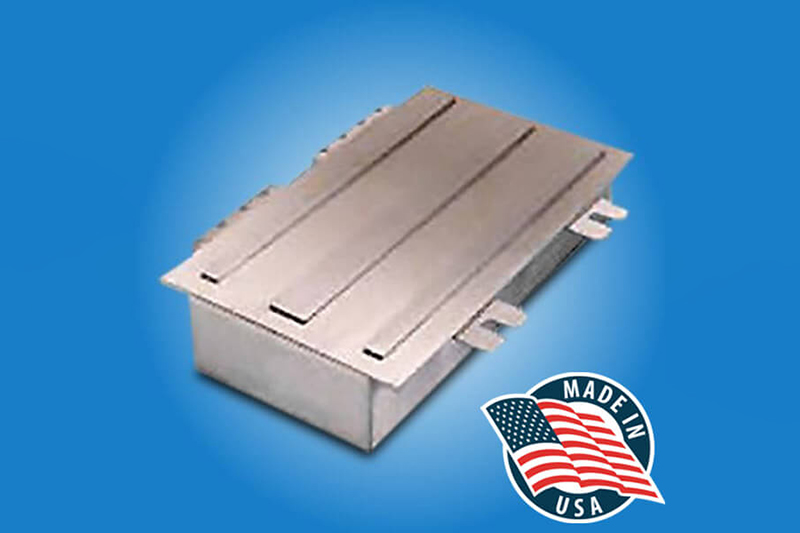

Type CM-3 Super Strength Conveyor Magnet

Conveyor Magnet for High Volume Industrial Flow

Our Type CM-3 is designed to remove larger ferrous metal such as bucket teeth, drill bits, and rebar from high-volume industrial flow. Capable of living items up to four inches below the unit, the Type CM-3 Super Strength Conveyor Magnet is a “no-maintenance” item and carries a lifetime guarantee on magnetic strength.

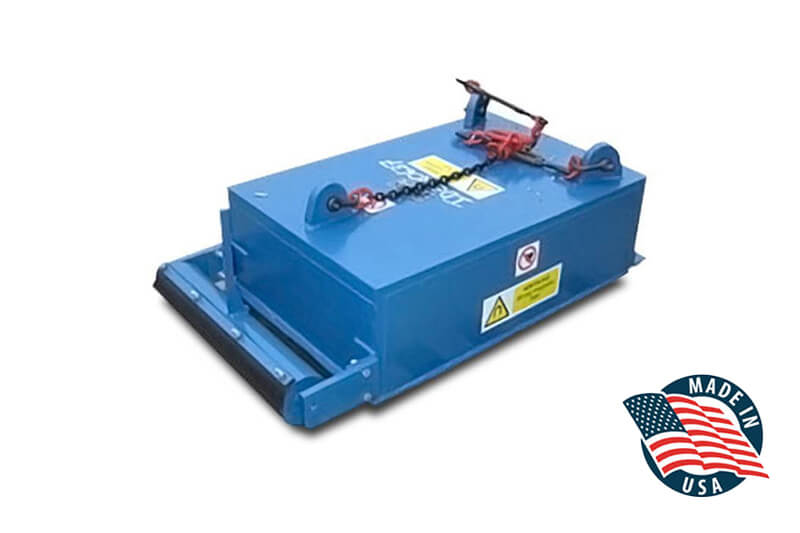

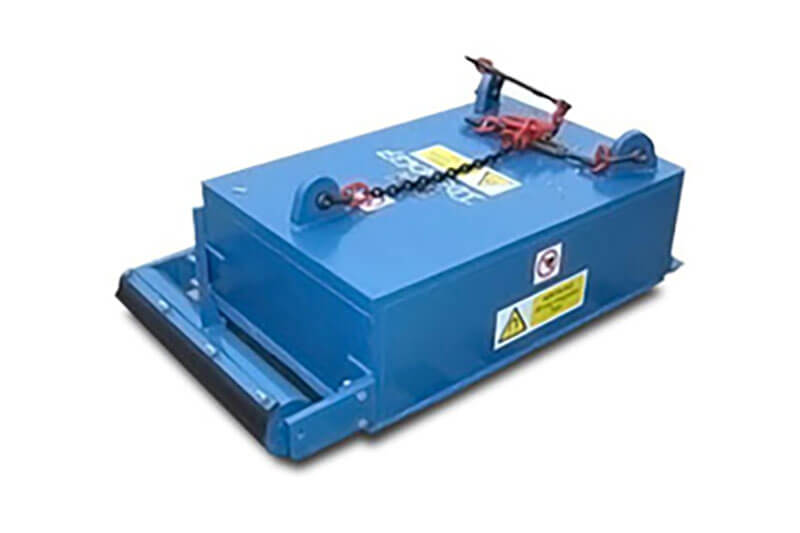

Type CM-1 Conveyor Magnet with Auto Release

Conveyor Magnet for Light to Medium Volume Industrial Flow

The Type CM-1 Conveyor Magnet is a versatile, portable and extremely effective way to remove random ferrous metal during product processing. Idea as back-up “Insurance Policy” when used in conjunction with a larger crossbelt magnet to retrieve small “fines” which get past the crossbelt, or as a stand-alone for light to medium volume industrial flow.

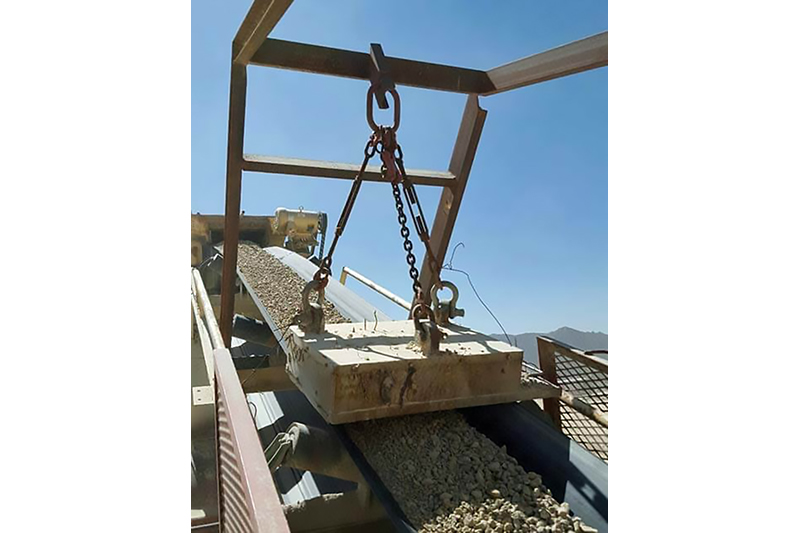

Stationary Separator Magnets

Permanent Magnetic Separator for Processing Environments

Permanent Suspension Magnets are designed specifically for the extraction of occasional tramp iron from material being processed on the conveyor belt, vibratory feeder or gravity chute. These overhead magnets are constructed using Grade 8 high power ceramic magnets and require no electricity, unlike electro type units.

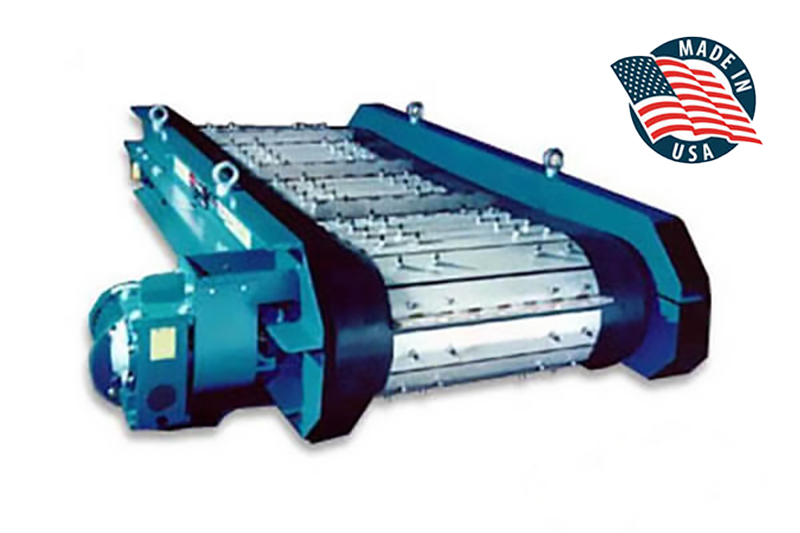

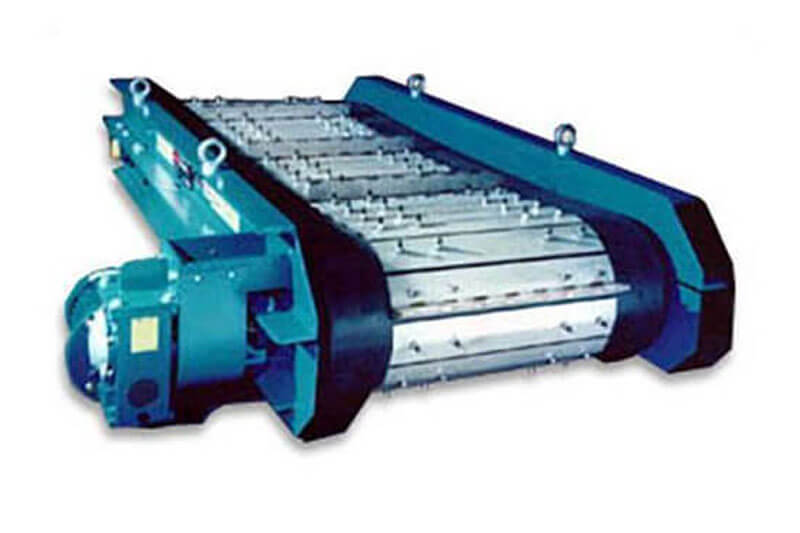

Cross-Belt Magnets

Overhead Magnetic Separator for Conveyor Belts

Cross-belt or belt magnets, also known as overhead magnetic separators, offer a practical and efficient method for separating ferrous metal from fast-moving materials on conveyors. Our belt magnets utilize Tri-Polar Magnetic Circuitry, exclusive to the industry.

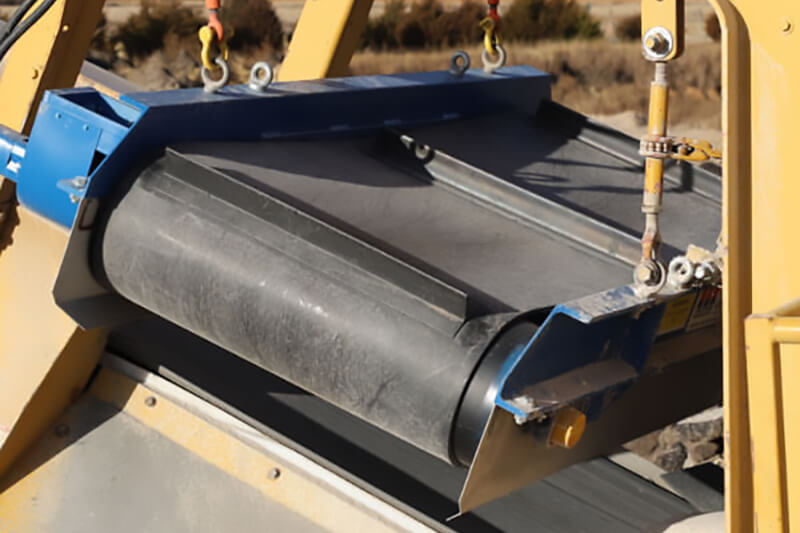

Magnetic Head Pulleys

Pulley Magnets Protect Against Tramp Iron Contamination

Our head pulleys and drum magnets provide continuous protection against tramp iron contamination of both large and fine metal particles. We offer magnet sizes for every application, as small as 4″ diameter. Our magnetic pulleys are available in regular strength and a “high power” version for more extreme applications.

Plate Magnets

Plate magnets are used to remove scrap metal from items such as grains, glass, chemicals, plastics, minerals and foodstuffs. Plate magnets are primarily used in ducts and chutes or suspended over conveyor belts.