Industrial Magnets For Food Processing Facilities

Shields Magnetics has been providing magnets to the food industry for forty years. Whether you need to remove ferrous metal from free flowing grains or liquid with an inline magnet or tramp iron from a conveyor belt with an overhead magnetic separator, we have a food grade solution for your application.

Protect food quality, prevent expensive recalls

During production, dangerous ferrous metal can contaminate everything from baby food and fruit juice to: grains, chocolate; flour; sauces; canned fruits and vegetables, meats and potato chips.

A single food recall can cost a manufacturer more than $10 million according to Food Safety Tech. Given the expense, lost product and production time and risk to your brand, ensuring the quality of your food stream with separator magnets is critical.

Shields Magnetics has been providing magnets to the food industry for forty years. Whether you need to remove ferrous metal from free flowing grains or liquid with an inline magnet or tramp iron from a conveyor belt with an overhead magnetic separator, we have a food grade solution for your application.

Operation

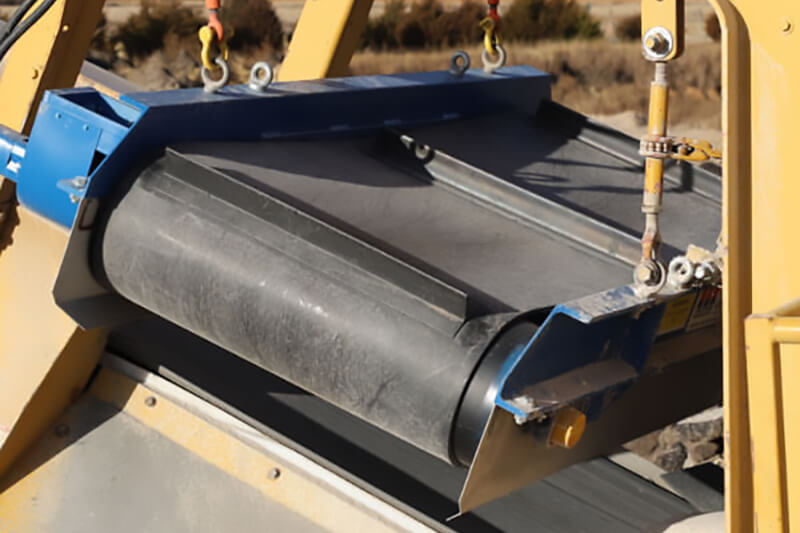

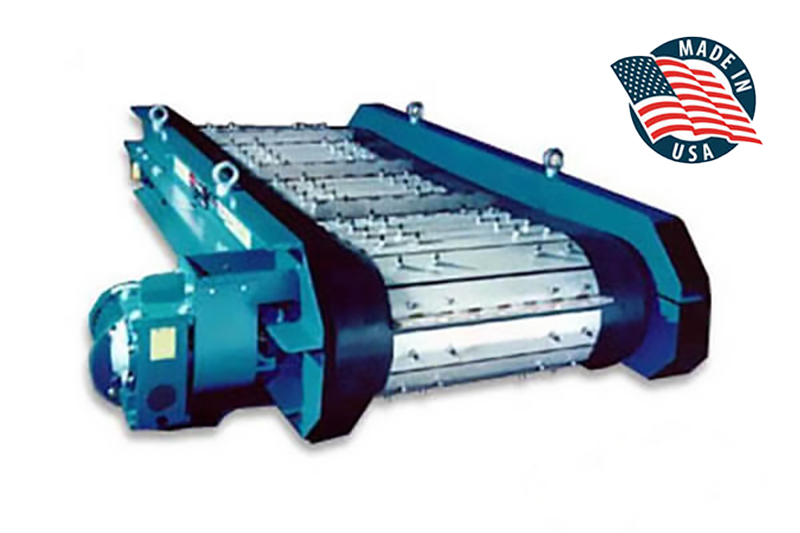

Conveyor Magnets, Belt Magnets and Separator Magnets play a key role in protecting food processing lines from dangerous ferrous metal. Monteted over the processing line or in chutes, magnets offer unmatched protection from scrap metal and dangerous product contamination:

Benefits

Enjoy hassle-free operation with our stainless food grade construction. Our total product purification process ensures that you can operate without the fear of line shutdowns from contamination or lack of cleanliness.

Every industrial magnet carries a lifetime guarantee on strength

Our entire line of magnetic separators carries a lifetime guarantee on strength and a full product performance guarantee.

All of our magnetic separators use powerful Grade 8 permanent magnets and can be ordered to spec. We also provide electromagnets when applications require such. We’ll work with your to customize a separation system that will fit your facility and application perfectly.